I Pengantar Pompa Kebakaran

Pompa pemadam kebakaran, sebagai peralatan inti pada truk pemadam kebakaran, memainkan peran penting Ini bukan hanya jantung dari sistem pemadam kebakaran, yang bertanggung jawab untuk menekan air dari sumber dan secara efisien mengirimkannya ke pemandangan api, tetapi juga kunci untuk memastikan operasi pemadam kebakaran yang lancar Desain dan pembuatan pompa api secara ketat mematuhi standar dan spesifikasi yang relevan untuk memastikan operasi yang stabil dan andal dalam berbagai situasi darurat

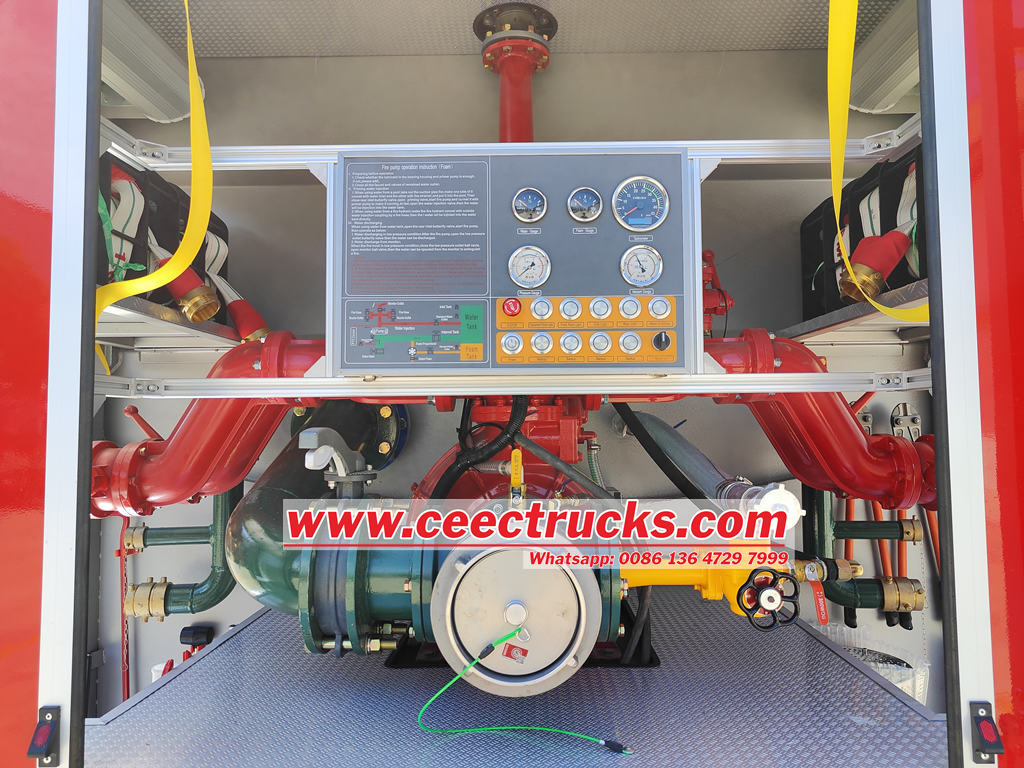

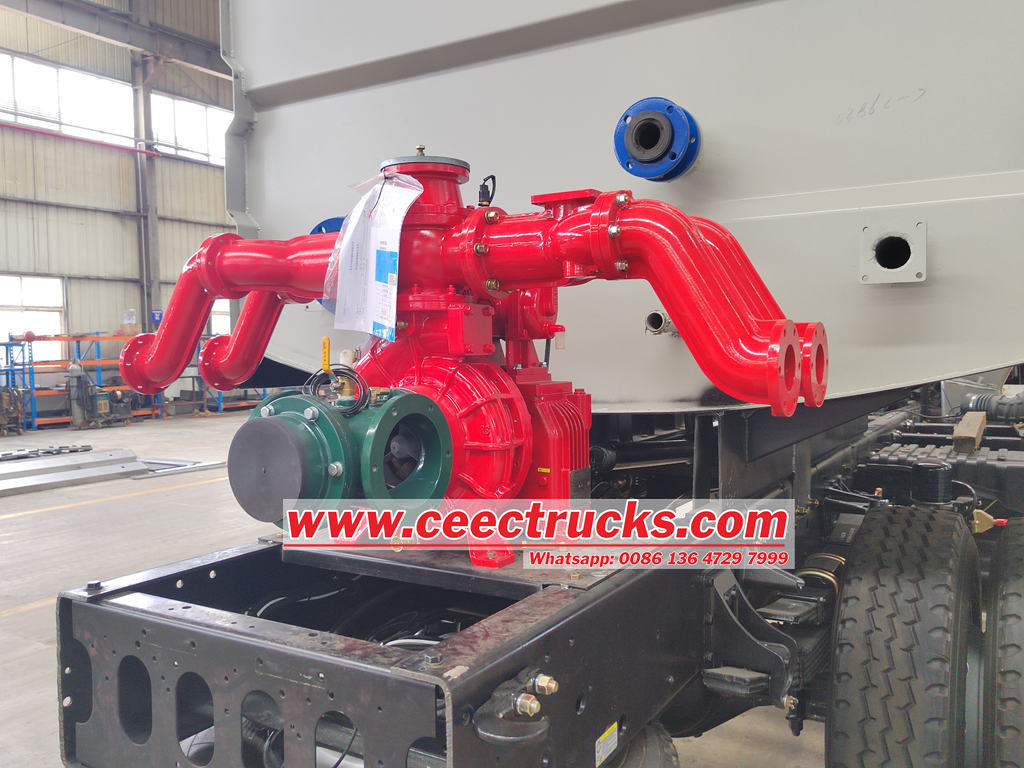

Pompa api biasanya terdiri dari komponen kunci seperti motor listrik, bodi pompa, impeller, segel, dan port inlet/outlet Motor listrik berfungsi sebagai sumber daya, mendorong impeller untuk memutar dan mengubah energi mekanik menjadi energi tekanan dan energi kinetik air Badan pompa bertanggung jawab untuk memuat dan membimbing aliran air, memastikan bahwa air melewati pompa dengan lancar dan mencapai tekanan yang diperlukan Impeller adalah komponen inti dari pompa api, dan bentuk serta kecepatan rotasinya secara langsung mempengaruhi laju aliran dan kepala pompa Segel digunakan untuk mencegah kebocoran air, memastikan efisiensi dan keamanan pompa

Di sebuah truk pemadam kebakaran, pompa pemadam kebakaran biasanya digunakan bersama dengan tangki air, meriam air, selang, dan peralatan pemadam kebakaran lainnya untuk membentuk sistem pemadam kebakaran yang lengkap Ketika kebakaran terjadi, pompa api dapat dimulai dengan cepat, menekan air dari sumbernya, dan mengirimkannya ke meriam air atau selang, yang kemudian menyemprotkan air ke tempat api untuk memadamkan api Oleh karena itu, kinerja dan keandalan pompa pemadam kebakaran terkait langsung dengan kemampuan dan efisiensi pemadam kebakaran truk pemadam kebakaran

Model pompa api yang umum digunakan ditampilkan dalam tabel berikut:

| Nama | Model | Kondisi kerja | Laju aliran (L/s) | Tekanan outlet (MPA) | Kecepatan Dinilai (r/mnt) | Kekuatan (KW) | Kedalaman hisap (M) |

| Pompa api bertekanan rendah | CB10/20-XZ | 1 | 20 | 1 | 3070±50 | 34. 29 | 3 |

| 2 | 14 | 1. 3 | 3380±50 | 35. 36 | 3 | ||

| 3 | 10 | 1 | 3115±50 | 27. 42 | 7 | ||

| Pompa api bertekanan rendah | CB10/30-XZ | 1 | 30 | 1 | 3010±50 | 50 | 3 |

| 2 | 21 | 1. 3 | 3340±50 | 55. 2 | 3 | ||

| 3 | 15 | 1 | 3000±50 | 38. 6 | 7 | ||

| Pompa api bertekanan rendah | CB10/40-XZ | 1 | 40 | 1 | 3080±50 | 62. 92 | 3 |

| 2 | 28 | 1. 3 | 3360±50 | 63. 92 | 3 | ||

| 3 | 20 | 1 | 2990±50 | 41. 95 | 7 | ||

| Pompa api bertekanan rendah | CB10/60-XZ(1:1. 346) | 1 | 60 | 1 | 3200±50 | 97. 72 | 3 |

| 2 | 42 | 1. 3 | 3475±50 | 105. 76 | 3 | ||

| 3 | 30 | 1 | 3130±50 | 72. 75 | 7 | ||

| Pompa api bertekanan rendah | CB10/80-XZ (1: 1 44) | 1 | 80 | 1 | 3400±50 | 137. 6 | 3 |

| 2 | 56 | 1. 3 | 3500±50 | 127. 11 | 3 | ||

| 3 | 40 | 1 | 3130±50 | 83. 75 | 7 | ||

| Pompa api bertekanan rendah | CB10/100-XZ | 1 | 100 | 1 | 2270±50 | 149 | 3 |

| 2 | 70 | 1. 3 | 2320±50 | 138 | 3 | ||

| 3 | 50 | 1 | 2050±50 | 115 | 7 |

Ii Kesalahan dan solusi umum untuk pompa pemadam kebakaran di truk pemadam kebakaran

Berikut ini adalah kesalahan umum dan solusinya untuk pompa pemadam kebakaran di truk pemadam kebakaran:

| Fenomena kesalahan | Kemungkinan penyebab | Solusi |

| Pompa tidak mengirimkan air, penunjuk pengukur tekanan melompat dengan keras | 1 Tingkat air di bawah pelat penutup belakang dari impeller tahap pertama 2 Kebocoran pipa atau instrumen | 1 Naikkan ketinggian air atau tingkatkan kedalaman perendaman pompa untuk memastikan asupan air yang normal 2 Periksa dan kencangkan atau blokir kebocoran untuk menghilangkan dampaknya pada operasi pompa |

| Pompa tidak mengirimkan air, pengukur tekanan menunjukkan tekanan | 1 Tekanan pipa outlet terlalu tinggi 2 Arah rotasi salah 3 Kecepatan rotasi tidak cukup | 1 Periksa dan peringkat dengan tepat pipa outlet untuk mengurangi tekanan outlet 2 Sesuaikan arah rotasi motor untuk memastikan konsistensi dengan persyaratan desain pompa 3 Periksa tegangan catu daya untuk memastikan kecepatan rotasi pompa memenuhi persyaratan desain, atau meningkatkan tegangan catu daya |

| Aliran yang tidak mencukupi atau kepala rendah | 1 Impeller atau pipa saluran masuk diblokir 2 Segel Ring sangat aus atau impeller rusak 3 Kecepatan rotasi di bawah nilai yang ditentukan | 1 Bersihkan impeller dan pipa untuk menghilangkan penyumbatan 2 Ganti cincin segel yang sangat usang atau impeller yang rusak tepat waktu 3 Sesuaikan kecepatan rotasi pompa untuk memastikannya mencapai nilai pengenal |

| Pompa mengkonsumsi daya yang berlebihan | 1 Kemasannya terlalu ketat 2 Panduan Panduan Pelumasan Tidak Cukup 3 Gesekan cincin segel 4 Laju aliran terlalu tinggi 5 Medium mengandung terlalu banyak kotoran | 1 Longgarkan kelenjar pengepakan dengan tepat untuk mengurangi beban pompa 2 Tingkatkan tekanan air pelumas dan laju aliran untuk memastikan pelumasan yang cukup dari bantalan panduan 3 Periksa dan hilangkan penyebab gesekan mekanis, seperti mengganti cincin segel yang usang 4 Periksa pembukaan katup gerbang untuk mengontrol laju aliran dalam rentang desain pompa 5 Kontrol kandungan pengotor dalam medium atau tingkatkan daya pencocokan untuk mengatasi konsumsi energi yang tinggi |

| Kebisingan abnormal di pompa, pompa tidak mengirimkan air | 1 Bantalan panduan sangat aus 2 Suhu cairan yang dipompa terlalu tinggi 3 Laju aliran pompa terlalu tinggi | 1 Periksa dan ganti bantalan pemandu usang untuk mengembalikan operasi pompa normal 2 Turunkan suhu cairan yang dipompa untuk memastikan pompa beroperasi dalam kisaran suhu yang sesuai 3 Kurangi pengaturan laju aliran pompa ke kisaran yang masuk akal |

| Getaran pompa yang tidak normal | 1 Bantalan panduan rusak 2 Poros pompa dan motor tidak konsentris 3 Baut jangkar longgar 4 Poros pompa dideformasi atau kopling longgar atau rusak | 1 Periksa dan ganti bantalan panduan yang rusak 2 Sejajarkan poros pompa dan motor untuk memastikan mereka konsentris 3 Kencangkan atau pour kembali baut jangkar untuk memastikan stabilitas pompa 4 Ganti poros pompa yang cacat atau rusak atau kopling |

| Rolling bearing overheats | 1 Pelumasan bantalan bergulir tidak cukup 2 Poros pompa dan motor tidak konsentris 3 Laju aliran dan kepala terlalu tinggi, menyebabkan pompa beroperasi kelebihan beban | 1 Periksa cangkir oli untuk memastikan bantalan bergulir menerima pelumas yang cukup 2 Sejajarkan poros pompa dan motor untuk mengurangi beban pada bantalan bergulir 3 Sesuaikan laju aliran dan kepala untuk memastikan operasi dalam kisaran penahan beban pompa |

| Pompa tidak bisa dimulai | 1 Masalah catu daya (seperti koneksi longgar, sakelar kontak yang buruk, kehilangan fase, dll.) 2 Kesalahan mekanis dalam pompa air (seperti pengepakan terlalu kencang, impeller dan bodi pompa macet oleh puing -puing, tekukan poros pompa yang parah, dll.) | 1 Periksa saluran listrik untuk kontak yang baik, dan pastikan sakelar berfungsi dengan baik Perbaiki istirahat sirkuit apa pun, kontak yang buruk, sekering yang ditiup, atau masalah kehilangan fase segera 2 Periksa komponen mekanis pompa air, seperti pengepakan, impeller, dan poros pompa, dan perbaiki atau ganti setiap bagian yang rusak atau tersumbat |

| Pompa tidak bisa menggambar air | 1 Udara di badan pompa atau udara yang terakumulasi dalam pipa saluran masuk 2 Katup kaki tidak tertutup rapat atau rusak 3 KEBOHONGAN PEMASAN POMPA KECAK 4 Katup gerbang atau katup periksa tidak tertutup rapat 5 Kebocoran pipa atau kedap udara | 1 Pompa prime dengan air terlebih dahulu, lalu isi badan pompa dengan air sebelum mulai 2 Periksa apakah katup kaki tertutup rapat atau ganti katup kaki yang rusak 3 Periksa pengemasan pompa vakum untuk kebocoran dan ganti jika perlu 4 Pastikan katup gerbang atau katup periksa ditutup rapat 5 Periksa pipa untuk kebocoran atau kedap udara dan perbaiki masalah apa pun segera |

| Pompa body bocor | 1 Segel berumur atau usang 2 Sambungan tubuh pompa longgar | 1 Periksa dan ganti segel tua atau usang 2 Kencangkan baut pada koneksi bodi pompa untuk memastikan penyegelan yang baik |

| Motor terlalu panas | 1 Tegangan terlalu tinggi atau terlalu rendah 2 Transmisi tidak halus (seperti mengandung kurangnya minyak, kerusakan, dll.) 3 Malfunction Sistem Ventilasi (seperti kerusakan kipas, penyumbatan saluran ventilasi, dll.) | 1 Periksa sistem catu daya untuk memastikan tegangan stabil dalam kisaran yang ditentukan 2 Periksa sistem transmisi untuk memastikan bantalan dilumasi secara memadai dan segera ganti bagian yang rusak 3 Periksa sistem ventilasi untuk memastikan kipas beroperasi secara normal dan saluran ventilasi tidak terhalang |

| Malfunction katup inlet/outlet | 1 Katup rusak 2 Katup tersumbat | 1 Ganti katup yang rusak 2 Bersihkan katup untuk menghilangkan puing -puing atau benda asing dan memastikannya tidak terhalang |

| Pipa hisap tersumbat | Puing -puing, sedimen, atau benda asing hadir di dalam pipa | Bersihkan pipa hisap untuk menghilangkan puing -puing, sedimen, atau benda asing |

| Pompa penstabil tekanan mulai sering | 1 Kebocoran pipa 2 Segel katup pelepas keselamatan buruk 3 Katup uji tidak tertutup rapat 4 Periksa bantalan segel katup terkontaminasi dengan kotoran 5 Pengaturan tekanan start-up sakelar tekanan terlalu tinggi 6 Sistem pipa bocor parah 7 Kapasitas tangki tekanan terlalu kecil | 1 Perbaiki kebocoran apa pun di dalam pipa 2 Periksa dan perbaiki katup pelepas keselamatan untuk memastikan penyegelan yang baik 3 Tutup sepenuhnya katup uji 4 Bersihkan katup periksa dan tangki air dan pipa 5 Sesuaikan pengaturan tekanan start-up sakelar tekanan ke kisaran yang wajar 6 Periksa pipa sistem dan perbaiki kebocoran apa pun 7 Tingkatkan kapasitas tangki tekanan atau ganti dengan setelan |

AKU AKU AKU Pencegahan dan pemeliharaan kegagalan pompa kebakaran

Untuk mengurangi kejadian kegagalan pompa kebakaran dan memperpanjang masa pakai mereka, perlu untuk melakukan pencegahan dan pemeliharaan pompa kebakaran yang efektif Berikut ini adalah beberapa saran:

(I) Inspeksi dan pemeliharaan secara teratur

1 Melakukan inspeksi rutin pompa api, termasuk kondisi kerja komponen seperti saluran listrik, motor, tubuh pompa, impeler, segel, katup, dan pipa

2 Segera perbaikan atau ganti komponen yang rusak atau tua berdasarkan hasil inspeksi

3 Lakukan perawatan rutin pada pompa api, seperti mengganti oli pelumas, impeler pembersih dan saluran pipa, dll

(Ii) Pastikan pemasangan dan operasi yang tepat

1 Selama pemasangan pompa api, secara ketat ikuti manual produk dan spesifikasi pemasangan untuk memastikan bahwa posisi pemasangan pompa, arah, sudut, dll., Memenuhi persyaratan

2 Saat mengoperasikan pompa kebakaran, ikuti prosedur operasi yang benar untuk menghindari kegagalan fungsi yang disebabkan oleh operasi yang tidak tepat Misalnya, pastikan bahwa bodi pompa diisi dengan air sebelum memulai pompa untuk mencegah kerusakan dari lari kering

(Iii) Perhatikan kualitas cairan

1 Pastikan kualitas cairan yang ditangani oleh pompa memenuhi persyaratan, menghindari kotoran berlebihan atau zat korosif dalam cairan yang dapat merusak pompa

2 Saat menggunakan pompa api untuk operasi pemadam kebakaran, perhatikan suhu cairan untuk menghindari efek samping pada kinerja pompa dan umur karena suhu yang terlalu tinggi atau rendah

(Iv) Jaga tubuh pompa tetap bersih

1 Secara teratur bersihkan bodi pompa untuk menghilangkan kotoran dan debu permukaan, mencegahnya mempengaruhi operasi normal pompa

2 Saat membersihkan badan pompa, berhati -hatilah agar tidak merusak segel dan koneksi pompa.